- Home Page

- Company Profile

-

Our Products

- Stearic Acid

- Food Additives

- Food Emulsifier

- Distilled Monoglycerides (E471)

- Distilled Monoglycerides (E471)

- My vatex

- Polyglycerol Polyricinoleate (PGPR)13

- Guar Gum

- Gms Powder

- Pectin .

- Polyglycerol Ester (PGE)

- Agar Agar

- Beta Carotene Suspension (Yellow to Orange)

- Annatto Oil Suspension (Orange to Red)

- Annatto Liquid (Orange to Yellow)

- Annatto Liquid Acid Stable (Orange to Red)

- Beta Carotene Powder (Orange)

- Black Carrot Powder Extract (Anthocyanin - Purple)

- Beetroot Red (Betanin Red)

- Chlorophyllin Liquid Powder (Green to Light Green)

- Vegetable Carbon (Black)

- Lutein (Yellow)

- Curcumin .

- Spirulina Powder Extract

- Ice Cream Stabilizer

- Cocoa Powder (Natural)

- Cocoa Powder (Alkalized Dutch)

- Bread Improver

- Butylated Hydroxy Anisole(BHA)

- Potassium Stearate

- Citric acid anhydrous

- Citric acid monohydrate

- Shelf Life Improver

- Anticaking agent

- Vitamin E

- Admul Emulsponge 5725

- Polyglycerol polyricinoleate (PGPR) 15

- Xanthan Gum

- Polymer Additives

- Proteins

- Industrial Chemicals

- Titanium Dioxide Anatase

- UV Absorber 770

- Di-Octyl Adipate (DOA)

- Dibenzoyl Methane (DBM)

- Ca-Zn Stabilizer

- Ca-Zn Powder PVC Stabilizer

- Ca-Zn Liquid PVC Stabilizer

- Calcium Hydroxide

- Calcium Carbonate Powder

- Ca Zn PVC One Pack Stabilizer

- Butyl Tin Maleate

- Ba-Ca-Zn Liquid PVC Stabilizer

- UV Absorber Benzophenone 12

- PVC Plastisizer

- Pharma Drugs

- Chemical Additives

- Zinc Stearate

- 12 Hydroxy Stearic Acid

- Pharma Raw Materials

- Chemical Reagents

- Chemical Supplies

- Wax Raw Materials

- PE Wax

- Fillers

- Rubber Chemicals

- Paint Raw Materials

- Pigments

- PVC Resins

- Pharmaceutical Excipients

- Adhesives & Sealants

- Castor Oil

- Plastic Raw Material

- Acid

- Synthetic Rubber

- Dyes

- Flavours

- Contact Us

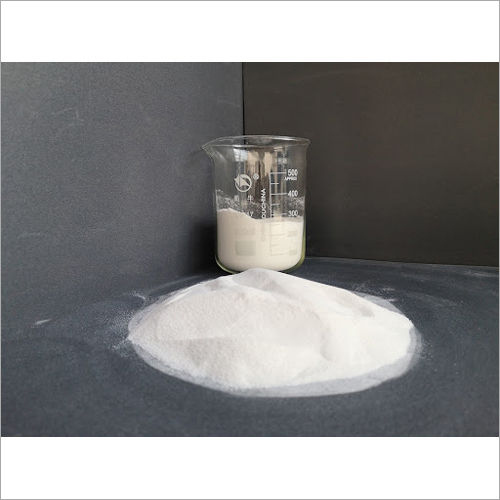

Acrylic Impact Modifier

12 -3400 INR/Kiloampere

Product Details:

- Melting Point >100C

- Poisonous No

- Shelf Life 2 Years

- Other Names AIM, Acrylic Modifier

- Application PVC Pipes and Profiles, Window Frames, Sheets

- Density 0.55 Gram per cubic centimeter(g/cm3)

- Grade Industrial Grade

- Click to View more

X

Acrylic Impact Modifier Price And Quantity

- 1000 Kilograms

- 12 -3400 INR/Kiloampere

Acrylic Impact Modifier Product Specifications

- Solid / Powder

- Plastic Industry

- Impact Modifier

- >99%

- Industrial Grade

- 2 Years

- AIM, Acrylic Modifier

- >100C

- Fine Powder

- Acrylic Impact Modifier

- No

- Powder

- White

- Cool and Dry Place

- Odorless

- Odorless

- 20-50 Microns

- PVC Pipes and Profiles, Window Frames, Sheets

- Insoluble in Water

- 0.55 Gram per cubic centimeter(g/cm3)

Acrylic Impact Modifier Trade Information

- 1000 Kilograms Per Month

- 7 Days

Product Description

Acrylic impact modifiers are materials used to increase the impact strength of plastics. They are typically used in the production of plastics that have to withstand extreme temperatures, impacts, or other physical stresses. These modifiers are generally composed of acrylic polymers and give the plastic increased flexibility, strength, and durability.

Product details

|

Bulk density |

0.45+/-0.10 g/cm3 |

|

Color |

White |

|

Form |

Powder |

|

Volatile content |

<=1.00 % |

|

Country of Origin |

Made in India |

|

Shelf Life |

24 Month |

|

Packaging Size |

20 Kg |

|

Usage/Application |

PVC window profile, PVC pipe and pipe fitting, PVC fence, PVC siding and decking, PVC panel,etc. |

Optimal Impact Resistance in PVC

Acrylic Impact Modifier effectively enhances the durability of PVC products, reducing the risk of cracking under physical stress. Its high compatibility ensures uniform dispersion, making it an ideal choice for manufacturing robust PVC pipes, window frames, and sheets. This additive delivers reliable results without compromising the aesthetics or processing performance of plastic goods.

Superior Heat Stability and Easy Processing

With its excellent heat stability and powdery fine particle size, this modifier simplifies integration into manufacturing lines. It retains physical integrity during extrusion, even at temperatures exceeding 100C, supporting high-output production. The consistent performance allows manufacturers to maintain product quality across long batches without extensive recalibration.

FAQ's of Acrylic Impact Modifier:

Q: How do I use Acrylic Impact Modifier in PVC formulations?

A: To use Acrylic Impact Modifier, incorporate 2-7 parts per hundred resin (phr) directly into your PVC blend during the compounding stage. Adjust dosage depending on the required impact resistance and application type, ensuring thorough mixing for optimal results.Q: What benefits does this impact modifier provide to the plastic industry?

A: Acrylic Impact Modifier delivers enhanced impact strength and outstanding heat stability, which increases the lifespan and safety of PVC products. Its high purity and fine powder ensure smooth processing, preventing defects and promoting consistent product quality.Q: When should Acrylic Impact Modifier be added during the manufacturing process?

A: It should be introduced during the initial blending or compounding stage with PVC resins and other additives. Adding it at this point guarantees even distribution, which is crucial for maximizing impact and mechanical benefits throughout the final product.Q: Where is this impact modifier commonly applied?

A: Acrylic Impact Modifier is widely used in the plastic industry, especially for manufacturing PVC pipes, profiles, window frames, and sheets. Its versatility makes it suitable for various extrusion and molding processes where improved toughness is required.Q: What steps should be taken for correct storage of the modifier?

A: Store the Acrylic Impact Modifier powder in a cool, dry place, away from sources of moisture and direct sunlight. Proper storage maintains its physical form and chemical integrity, preserving its efficacy for up to 2 years.Q: What is the main advantage of using this modifier over alternatives?

A: Its high compatibility with PVC, excellent impact enhancement, and reliable heat stability set it apart from other modifiers. These attributes result in superior product durability, operational efficiency, and minimized risk of processing defects.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Chemical Additives' category

|

CHEMVERA SPECIALITY CHEMICALS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free