- Home Page

- Company Profile

-

Our Products

- Stearic Acid

- Food Additives

- Food Emulsifier

- Distilled Monoglycerides (E471)

- Distilled Monoglycerides (E471)

- My vatex

- Polyglycerol Polyricinoleate (PGPR)13

- Guar Gum

- Gms Powder

- Pectin .

- Polyglycerol Ester (PGE)

- Agar Agar

- Beta Carotene Suspension (Yellow to Orange)

- Annatto Oil Suspension (Orange to Red)

- Annatto Liquid (Orange to Yellow)

- Annatto Liquid Acid Stable (Orange to Red)

- Beta Carotene Powder (Orange)

- Black Carrot Powder Extract (Anthocyanin - Purple)

- Beetroot Red (Betanin Red)

- Chlorophyllin Liquid Powder (Green to Light Green)

- Vegetable Carbon (Black)

- Lutein (Yellow)

- Curcumin .

- Spirulina Powder Extract

- Ice Cream Stabilizer

- Cocoa Powder (Natural)

- Cocoa Powder (Alkalized Dutch)

- Bread Improver

- Butylated Hydroxy Anisole(BHA)

- Potassium Stearate

- Citric acid anhydrous

- Citric acid monohydrate

- Shelf Life Improver

- Anticaking agent

- Vitamin E

- Admul Emulsponge 5725

- Polyglycerol polyricinoleate (PGPR) 15

- Xanthan Gum

- Polymer Additives

- Proteins

- Industrial Chemicals

- Titanium Dioxide Anatase

- UV Absorber 770

- Di-Octyl Adipate (DOA)

- Dibenzoyl Methane (DBM)

- Ca-Zn Stabilizer

- Ca-Zn Powder PVC Stabilizer

- Ca-Zn Liquid PVC Stabilizer

- Calcium Hydroxide

- Calcium Carbonate Powder

- Ca Zn PVC One Pack Stabilizer

- Butyl Tin Maleate

- Ba-Ca-Zn Liquid PVC Stabilizer

- UV Absorber Benzophenone 12

- PVC Plastisizer

- Pharma Drugs

- Chemical Additives

- Zinc Stearate

- 12 Hydroxy Stearic Acid

- Pharma Raw Materials

- Chemical Reagents

- Chemical Supplies

- Wax Raw Materials

- PE Wax

- Fillers

- Rubber Chemicals

- Paint Raw Materials

- Pigments

- PVC Resins

- Pharmaceutical Excipients

- Adhesives & Sealants

- Castor Oil

- Plastic Raw Material

- Acid

- Synthetic Rubber

- Dyes

- Flavours

- Contact Us

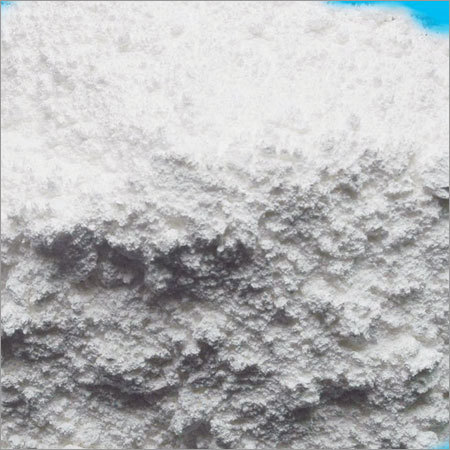

Zinc Stearate Powder

94.00 - 102.00 INR/Kilograms

Product Details:

- Usage Additive in polymers, release agent, anti-caking agent, stabilizer.

- Density 1.09 Gram per cubic centimeter(g/cm3)

- Solubility Insoluble in water, soluble in aromatic hydrocarbons and chlorinated hydrocarbons.

- Taste Odorless, Tasteless

- Structural Formula [CH3(CH2)16COO]2Zn

- HS Code 29157090

- Properties Excellent lubricating properties, hydrophobic, non-toxic, fine white powder, insoluble in water.

- Click to View more

X

Zinc Stearate Powder Price And Quantity

- 500 Kilograms

- 94.00 - 102.00 INR/Kilograms

Zinc Stearate Powder Product Specifications

- 99%

- Excellent lubricating properties, hydrophobic, non-toxic, fine white powder, insoluble in water.

- 557-05-1

- Zinc Stearate

- Fine White Powder

- Zinc Stearate

- 24 Months

- Additive in polymers, release agent, anti-caking agent, stabilizer.

- 1.09 Gram per cubic centimeter(g/cm3)

- Insoluble in water, soluble in aromatic hydrocarbons and chlorinated hydrocarbons.

- Odorless, Tasteless

- 29157090

- [CH3(CH2)16COO]2Zn

- Industrial Grade

- 632.34 g/mol

- Used as a release agent, lubricant, and mold release agent in plastic, rubber, paint, and cosmetics industries.

- Odorless

- Keep tightly closed in cool, dry, well-ventilated area, away from incompatible substances.

- NO

- C36H70O4Zn

- Powdered Form

- 209-151-9

- Powder

- 120-130C

- 7 (neutral)

Zinc Stearate Powder Trade Information

- 1000 Kilograms Per Month

- 7 Days

Product Description

We have carved a niche in this domain by manufacturing, exporting and supplying a wide range of Zinc Stearate. This stearate is processed under the guidance of ingenious professionals using quality tested chemical compounds at our advanced production unit. Offered stearate is extensively used in detergents, paints and soaps for imparting gloss. Besides, this Zinc Stearate can be availed from us at industry leading rates within stipulated time frame.

Key Points:

- Insoluble in water and alcohol

- Free from impurities

- Longer shelf life

- Accurate pH value

Product details

|

Ash Content |

15 % |

|

Bulk Density |

0.4 g/cc |

|

Fineness |

200 mesh |

|

Form |

Fine Powder |

|

Free Fatty Acid Content |

< 1% |

|

Heavy Metal Impurities |

< 40 ppm |

|

Packaging Type |

Bag |

|

Specific Gravity |

1.10 |

|

Usage/Applications |

Release Agent, Heat Stabilizer And Lubricant In The Plastics, Polyolefin and Rubber Industry |

|

Volatile Content |

< 2% |

|

Melting Point |

126 degree C |

|

Chemical Formula |

C36H70O4Zn |

|

Purity % |

99% |

|

CAS No |

557-05-1 |

Outstanding Lubricant and Release Agent

Zinc Stearate Powder is prized for its exceptional lubricating and mold-release capabilities, making it ideal for facilitating smooth processing in polymer, rubber, and plastic manufacturing. Its fine particle size ensures uniform performance as a release and anti-caking agent, while its hydrophobic characteristics prevent moisture absorption. Benefit from increased efficiency and product quality in your industrial applications.

Physical Properties and Safe Handling

With a neutral pH, high purity, and non-toxic nature, Zinc Stearate offers consistent results while ensuring safety during handling. It demonstrates a melting point of 120130C and is insoluble in water, providing stability under various processing conditions. For longevity, store the powder in a tightly closed container, protected from moisture, and away from incompatible substances.

FAQs of Zinc Stearate Powder:

Q: How is Zinc Stearate Powder typically used in industrial applications?

A: Zinc Stearate Powder is commonly used as a release agent, lubricant, anti-caking agent, and stabilizer in industries such as plastics, rubber, paint, and cosmetics. It facilitates easy demolding, improves surface finish, prevents clumping, and enhances process efficiency.Q: What benefits does Zinc Stearate offer compared to other lubricants or release agents?

A: Zinc Stearate is highly prized for its excellent lubricating and hydrophobic properties, fine particle size, non-toxicity, and ease of use. It imparts a superior surface finish and is especially effective in moisture-prone environments due to its water-insoluble nature.Q: When should Zinc Stearate Powder be added during the manufacturing process?

A: In most applications, Zinc Stearate is added during the mixing or compounding stage of polymer or rubber processing to ensure even dispersion and optimal performance as a release agent or lubricant.Q: Where should Zinc Stearate Powder be stored for maximum shelf life?

A: For best results, Zinc Stearate Powder should be kept in a tightly closed container in a cool, dry, and well-ventilated area, away from direct sunlight, moisture, and incompatible substances. This preserves its quality and extends its shelf life up to 24 months.Q: What safety measures should be followed when handling Zinc Stearate Powder?

A: Although Zinc Stearate is non-toxic under normal use, it is advisable to use standard industry precautions such as wearing protective clothing and working in ventilated areas to prevent inhalation of fine powder.Q: Is Zinc Stearate Powder safe and environmentally friendly?

A: Yes, Zinc Stearate Powder is non-toxic, odorless, tasteless, and exhibits no poisonous effects under standard handling and use, making it suitable for various industrial applications without significant environmental or health concerns.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

CHEMVERA SPECIALITY CHEMICALS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS